Heating Mantles

When performing controlled chemical reactions, one of the essential pieces of equipment needed in the laboratory is the heating mantle. This device is commonly used to apply uniform heat to round-bottom flasks during a chemical reaction or distillation process. Heating mantles provide a controlled and safe way to heat chemicals that require specific temperatures, avoiding the risks associated with other heating methods, such as using Bunsen burners.

In my personal experience, heating mantles are indispensable in any chemistry lab. I have worked with different types of samples, from organic compounds to more complex substances, and it’s always essential to maintain precise temperature control to avoid decomposition or unwanted reactions. Moreover, heating mantles allow for more even heat distribution in the container, which is critical for ensuring the stability of reactions.

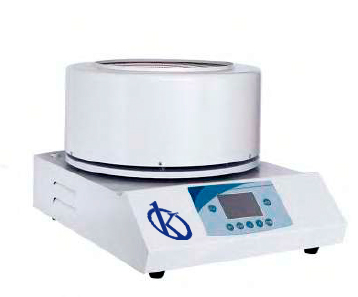

Heating Mantles, KALSTEIN Brand

Kalstein is a brand that has established itself as a leader in manufacturing high-quality laboratory equipment, and its heating mantles are no exception. What has impressed me most about Kalstein heating mantles is their robust design and ease of use. Additionally, these devices allow for precise temperature control, which is key in chemical reactions where just a few degrees difference can alter the results.

A standout feature of Kalstein heating mantles is their safety. Unlike other heating methods, these mantles are designed to minimize the risk of burns or accidents, as the heat is concentrated on the container and does not radiate into the surroundings. This not only protects the operator but also prevents potential interference in measurements caused by high ambient heat. Moreover, Kalstein offers constant technical support, which is a great advantage for any laboratory looking for reliable and durable equipment.

Features of Heating Mantles

The heating mantles from Kalstein are designed with features that make them stand out in the market. First, their ability to provide uniform heating is essential to avoid uneven heating of substances, which could lead to errors in experiments. Kalstein mantles are made from heat-resistant materials, ensuring a long lifespan even under intensive use.

Another important feature is versatility. Kalstein heating mantles come in different sizes and configurations, making them suitable for a wide range of laboratory applications. Some models also include a built-in stirrer, which facilitates simultaneous stirring and heating of substances, improving process efficiency.

Different Types or Models of Heating Mantles

Kalstein offers a wide range of heating mantle models that cater to the needs of different types of laboratories. One of the most common models is the standard heating mantle, designed to heat round-bottom flasks of various sizes. These mantles are ideal for chemical synthesis and distillation work, as they provide consistent and controlled heating.

Another type of heating mantle is the model with a built-in stirrer, which is ideal for reactions that require continuous stirring during heating. This type of mantle is particularly useful in organic synthesis, where constant agitation can be key to reaction efficiency. Additionally, Kalstein also offers high-performance heating mantles designed to work at extremely high temperatures, making them suitable for industrial processes or reactions that require specific thermal conditions.

Why Do Heating Mantles Have This Price?

The price of heating mantles is directly related to the quality of materials and technology used. Kalstein heating mantles are made from high-resistance materials, ensuring durability and long-term performance. Moreover, the inclusion of advanced technologies such as digital temperature control and safety systems increases their value.

When comparing the prices of Kalstein heating mantles with other brands such as IKA, Heidolph, and Fisher Scientific, the price is competitive given the quality offered. While some brands like IKA may have similar products, Kalstein heating mantles provide an excellent price-to-quality ratio, offering similar technical features at a more affordable cost.

Comparison of Heating Mantles with Similar Products

When comparing Kalstein heating mantles with products from brands like IKA, Heidolph, and Fisher Scientific, several key differences emerge. First, Kalstein models offer precise temperature control, similar to Heidolph, but at a more competitive price. Additionally, Kalstein mantles are known for their durability, making them an ideal option for labs with intensive use of this equipment.

Compared to IKA products, Kalstein offers models that include additional features, such as the built-in stirrer, at a lower cost. Fisher Scientific, on the other hand, offers high-quality products, but often at higher prices, which may not be the most cost-effective option for laboratories with tighter budgets.

Pros and Cons of Heating Mantles

| Pros | Cons |

| Precise temperature control | Requires regular maintenance to ensure efficiency |

| Available in a wide range of sizes and models | Some models may be costly for small labs |

| Versatility for different types of applications | There may be a learning curve for some users |

| Built-in stirring function in certain models | Heating time may be longer in some cases |

| Heat-resistant materials ensuring durability | External wiring may take up space in the lab |

| Enhanced safety thanks to design that concentrates heat on the container | Requires a constant power supply |

| Easy to use, even for beginners | Some advanced models may require specific training |

| Excellent price-to-quality ratio |

Benefits of Using These Heating Mantles

The use of a heating mantle, especially one from Kalstein, provides multiple benefits in the laboratory. One of the main benefits is the ability to maintain precise temperature control, which is crucial for delicate chemical reactions. I have worked with compounds that are extremely sensitive to temperature variations, and Kalstein heating mantles have allowed me to carry out experiments with a level of precision that cannot be achieved with conventional heating methods.

Another important benefit is the safety they offer. Unlike other methods such as Bunsen burners, Kalstein heating mantles are designed to minimize the risk of accidents, making them ideal for laboratories where hazardous substances or exothermic reactions are handled.

Other Advantages of Heating Mantles

In addition to direct benefits in terms of control and safety, Kalstein heating mantles offer several additional advantages. For instance, their compact design helps save space in the laboratory, something that is always appreciated in facilities where space is limited. Moreover, the ease of use is another aspect that has impressed me. Even novice users can operate these heating mantles with relative ease thanks to their intuitive interface.

I have also noticed that the maintenance of these units is straightforward, significantly reducing downtime in the laboratory. This is particularly important in environments where execution times are critical, and any delay can affect experimental results.

User References about Heating Mantles

Many users who have purchased Kalstein heating mantles agree on their excellent performance and reliability. A chemist in a research lab mentioned: “This heating mantle has significantly improved our ability to conduct controlled reactions without overheating issues.” Another user from a university highlighted: “The ease of use and robust design make it an indispensable tool in our daily experiments.”

Frequently Asked Questions

- What size heating mantle should I choose?

The size depends on the volume of the flask you will be using. Kalstein offers mantles in various sizes to suit different needs. - Is it difficult to use a heating mantle?

No, Kalstein heating mantles have an easy-to-use interface. However, it is recommended to become familiar with the equipment before performing more complex experiments. - Can a heating mantle be used for all chemical reactions?

Yes, heating mantles are suitable for a wide variety of chemical reactions, as long as the temperature is properly adjusted. - How long does it take for a heating mantle to heat up?

Heating time varies depending on the model, but in general, Kalstein heating mantles are fast and efficient. - Do heating mantles require much maintenance?

No, they only require basic, regular maintenance to ensure optimal operation. - Why should I choose a Kalstein heating mantle?

Kalstein offers excellent value for money, with durable models and advanced technology that ensures precise and safe heating.

Final Recommendations on These Heating Mantles

In conclusion, Kalstein heating mantles are a valuable investment for any laboratory that needs to perform chemical reactions with precise control. Their ease of use, enhanced safety, and durability make them a standout option compared to other brands in the market. If you’re looking to improve your lab’s efficiency, you should definitely consider a Kalstein heating mantle.

Do you long for top-quality medical equipment, ready to boost the efficiency of your lab? Visit kalstein.com.eg to explore our high-end catalog, packed with the best finds at the most competitive prices. Excellence is our hallmark. We innovate and manufacture high-precision equipment, both reliable and durable, to meet your needs. Why wait? Make your purchase online quickly and safely, and take the leap into the future of medical technology today. kalstein.com.eg